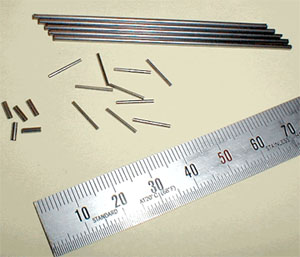

|  The cathole sleeve is a key component in the heart of the kinesope electron gun, with the following capabilities: The cathole sleeve is a key component in the heart of the kinesope electron gun, with the following capabilities:

①High heat resistance(using nickel-base alloy).

②High heat absorptivity and exothermicity(wall thickness 20μm or so).

③High dimension precision(restrain the influence of heat retractility).

④High cleanness(can be used in high vacuum).

At present, the part uses nickiel-base alloy as the material such as nickel chrome alloy, kovar and iron-nickel alloy etc. The part, that is produced with drawing process technology, has many characteristics such as high dimension precision of wall thickness (the wall thickness is 20μm, dimensional tolerance within ±0.002). And the final product has a high demand on cleanness.

The manufacturing technology of cathole sleeves used in our company can be extensively applied to the manufacturing field of other precision tubes.

|

|

|

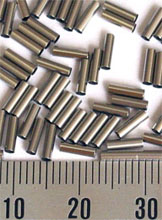

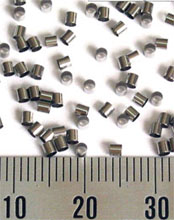

| Iron-Nickel Tubes |

Nickel-Chromium Tubes |

Kovar Tubes |

Nickel & Nickel Alloy

Nickel, iron-nickel, Kovar, Inconel #600, nickel-chromium, Monel metal, Permalloy, chrome-nickel alloy and other nickel-base alloy.

Besides those mentioned above, we can also process the following materials. Please contact us to discuss.

Copper & Copper Alloy

Oxygen-free coper, brass, phosphor bronze, and cupronickel.

Stainless Steel

SUS303、SUS304、 SUS316L、SUS420、SUS430

Special Metal & Alloy

Tantalum, titanium, molybdenum, niobium, gold, silver, platinum, aluminium and other special alloy. |

|

|

Material:

|

|

|